DENNIS M. THIMM, MS. CMR, CASE WESTERN RESERVE UNIVERSITY, FLEXPOST, INC.

ABSTRACT:

The challenge of directing and orienting traffic into parking spaces has become a major problem among retail organizations nation-wide. The data gathered in this paper will examine the increased need to orient customers to specific parking spaces, the challenges associated with a convergence of employees and customers into an assigned parking area, and the costs associated with the installation and maintenance of buy online-pick up spaces signage and bollards.

INTRODUCTION:

The fast pace of the average American lifestyle, the click and buy deliver next day impulsiveness of the Amazon generation, and a pandemic have conditioned American shoppers into worry and concern over simple tasks such as entering a store. Suddenly, interacting with and around strangers and public spaces seems daunting and the safety of our own cars has become the transaction point at many grocery stores. While countermeasures such as masks and protective barriers appear to be marginally beneficial, the reluctance to enter a store prevails. At the time of this writing, new legislation in California, Michigan and many other states continues to confuse and concern retail shoppers. The trend towards app. driven and buy online and drive up pick up has exploded in the last several months. Retailers and restaurant chains have struggled to orient, educate, and serve their customers in confined areas within their parking lots. Most pick-up areas within large grocery store chains are limited to approximately 2-6 spaces, and typically located within 40 yards from the front egress of the store. With an average of 23,000 patrons walking through the door of a large supercenter per day, it is not hard to imagine the peril, potential accidents, property damage, and damage to customer vehicles. While the convergence of traffic proximal to the front door of major retail organizations is certainly good for business, the number of car sign collisions has skyrocketed by nearly 375%.1

Collisions involving customers and retail Buy Online, Pickup In-Store (BOPIS) signage within a parking lot has become a major issue causing millions of dollars’ worth of damage per year. As of 2019, an average retail organization would replace approximately 2-3 signs and posts per year, both in the ADA handicapped and BOPIS aisle, with an average cost of $900 +/- per required repair. Now that retailers are adding multiple signs/posts to their already crowded and confused lots, the car/post accidents are escalating. A major international retailer located in the south recently relayed that of the average 9 buy online pick up spaces located at each store, collisions require them to repair and replace 3 of their BOPIS signs and bollards quarterly. When the retailer examined the overall costs of the repairs, 3 posts/signs per quarter multiplied by over 4,500 US stores alone, the staggering costs of the program amounted to approximately $8,400 per store, or a combined loss of revenue of $37,000,000 per year.

ALTERNATIVES:

Major retailers utilize a broad range of signposts and bollard products to display necessary signage in their parking lots.

With each of the alternatives available, there are inherent plusses and minuses, costs, and most importantly, repair costs.

While the average price of a concrete pyramid base might be $200.00/each, the cost to transport and install that sign base approaches $475.00/ea. when the price of shipping and delivery are considered.

Rigid bollards with signposts are also a popular solution for use in retail lots. Among the limitations associated with a rigid bollard are the complexity of installation which involves large equipment, concrete trucks, multiple skilled laborers, and the cordoning off large areas of traffic to allow for equipment. The result is a disruption of traffic flows, and a messy clean up after installation.

A major limiting factor of bollard posts is the cost associated with the initial installation and repair upon impact. A broad survey among major retail organizations revealed that the price per installation of a rigid bollard/signpost is nearly $950.00/each2.

While rigid bollards withstand impacts up to 10mph, their longevity is greatly limited due to impacts over that speed.

The unsightly appearance of bent wayfinding signage detracts from the appearance of the store and creates an impression of disrepair. Even a minor collision with a rigid bollard can cause damage to the signpost, the automobile, and the parking surface. The net result is a customer who will likely not shop that store on the day of the impact, a costly repair to the patron’s vehicle, and possible litigation to the property owner or management company. Upon routine impact, the price to make a repair to a rigid bollard is bollard averages $1,250.003 each.

More recently, the invention and refinement of flexible spring-loaded bollards and signposts with bollard covers have been widely used to mitigate the ongoing problem of repairing signposts and bollards in busy parking areas.

METHODOLOGY:

The objective of this study is to better understand the long-term costs of installing and maintaining BOPIS parking spaces program-wide in busy retail settings. Though the purpose of this study is to consider repair costs for pick up spaces, these data would extrapolate to other signage including ADA handicapped spaces, wayfinding signage and stop signs within retail parking lots and structures.

To establish the mean installation costs associated with signposts, extensive surveys have been conducted within retail organizations. Involved with this project have been several facility maintenance planners, civil engineers and architects.

It was found that the national average to install one rigid bollard with an 8’ or 9’ signpost is $909.254, n=37 respondents. To establish the mean repair and replacement costs associated with the repair and or replacement of a rigid bollard, extensive surveys have been conducted with both local and regional installers, asphalt contractors, pavers, and maintenance professionals. The mean cost of repairing or replacing a bent bollard or signpost is $1,129.545, n=33 respondents.

A major retail organization located in Florida commenced a large scale roll out of their buy on-line pick up in store program in 2018. To facilitate rapid installation and minimize disruption to the parking areas, a change was made to the specifications for parking signage, and a custom color, custom sign flexible signpost was chosen over the rigid bollard specification.

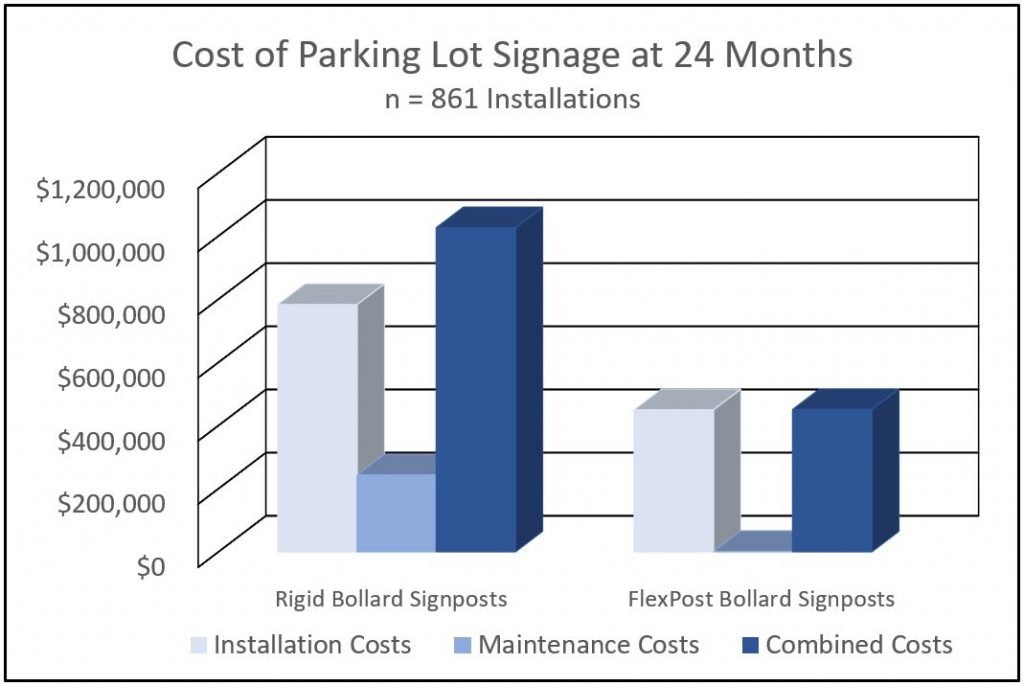

See chart below for costs of the program vs. extrapolated repair costs of using rigid bollards.

DISCUSSION:

As retailers and restaurants struggle with orienting traffic flows in and out of tight parking lots, many signage and wayfinding alternatives must be employed. The invention and perfection of a flexible signpost and flexible signpost/bollard was necessary to minimize damage to parking lots, cars, and parking structures.

Early versions of flexible signposts/bollards were tested and proven to be impractical. Early versions were constructed of plastics which did not weather the direct sunlight, cracked in cold temperatures and induced pedestrians to tamper with them. A major undertaking was initiated in 2007 to design a solution with the following characteristics:

- Withstand high winds with standard size signage.

- Withstand high winds with large regulatory signage.

- A full 3600 range of motion to avoid the damage of multidirectional impacts.

- Meet failure criteria to provide for the safety cars and pedestrians.

- Simple surface anchored installation minimizing the need for disruption of traffic flows in busy parking areas. Installation to be accomplished without pouring a concrete pad or use messy adhesives or epoxies.

- A device that could be installed with no special tools, licenses or training by store or maintenance personnel.

- Concealed spring to minimize the temptation for pedestrian tampering.

- Made in the USA.

- A lifetime guarantee against breakage when used in a parking lot under normal circumstances.

- Easily customizable heights, colors, and designs to allow for the proper marketing message and signage to be displayed on the product.

SOLUTION:

A highly durable, flexible signpost solution began to evolve in 2009 utilizing a simple coiled carbon steel spring. As casting and metal stamping technology improved an innovative design was tested and perfected to meet the failure criteria required for busy institutional parking lots such as major retail, airports, hospitals.

A novel two piece, 19-pound stamped 7-gauge HRPO steel base was tested, and perfected. The steel base incorporates an industry standard 2 3/8” post. The halves are joined with a ¼” stainless steel cable tested to minimum breaking strength 7,000 lbs., and compress 5/16″ high carbon steel spring. The calculated wind resistance of the FlexPost-XL™ base was surprising, yielding only a few degrees of flexion at 75mph gusts even with large regulatory signage attached. The base and post combination has proven safe and durable for large scale applications. While the conceivable life of a sign base would be approximately 7-8 years, the Flexpost® base is covered with a lifetime guarantee when installed in a parking lot.

Among the variables for considering the lifespan of a parking lot sign system is the overall condition and thickness of the Asphalt substrate. The Bolthold™ Asphalt Anchor family which incorporate zinc coated treaded spikes cemented into asphalt has been used with great success. These anchors have been thoroughly tested and are supplied with each Flexpost-Xli Bollard/Signpost.

The Bolthold family of anchors tested and selected are known to resist pull out in the following thicknesses of asphalt:

50mm (2” asphalt thickness) = 1,500 pull force lbs.

100mm (4” asphalt thickness) = 2,000 pull force lbs.

1500mm (6” asphalt thickness) = 2,180 pull force lbs.

CONCLUSION:

Alternatives to parking lot signage and posts are many, each with their inherent strengths and weaknesses, and each requires maintenance and surveillance.

While retail organizations struggle to find a cost-effective solution, most fail to calculate the huge costs associated with repair and replacement of rigid bollards and u-channel signposts.

A retrospective analysis of a stepped installation of 861 FlexPost-XL signposts since 2018 proved a failure rate of 2 units over 25 months, or combined failure rate of .232%. The total cost of the repairs required for the 2 partially damaged posts was a mere $1,012 (p=.003). The amount spent on repair parts in total was less than .225% of the total capital expenditure of the program.

Compared to a concrete filled parking bollard/signpost at an average cost of $909.25 ea. and with a repair cost of $1,129.54 ea. the Flexible Signpost was not only far less expensive to purchase, required only 25 minutes to install and withstood repeated impacts. The elimination of front-end costs and especially maintenance costs were substantial.

The average life span of a signpost in a parking lot varies, however an industry norm is to repair or replace 25-30% of a stores rigid bollard annually.

Costs associated with the installation of the 861 rigid bollards would have been $782,864 for installation. Considering the frequency of damage upon impact, there would have been the need to replace a minimum of 215 posts at a cost of $243,133. The combined cost of the program using rigid bollards would have been $1,025,997. The combined cost of installation and repair of the same program using a Flexpost-XL Bollard/Sign post was proven to be 43% less expensive for this retail chain.

In addition to the minimum of repair costs, the retailer reported no litigation filed in relation to the impact of a bollard, likely adding to the savings.

REFERENCES:

[1] A survey of retail organizations and their reported cost of maintenance, poster-exhibit, National Parking Association, 2019

[2] [4] DeYoung, John E, Et. Al., A longitudinal survey of asphalt installers and maintenance professionals, National Paving Exposition, 2019

[3] [5] Thimm, Dennis Et. Al., A survey of asphalt installers and maintenance professionals, white paper, National Paving Expo, 2019

Interested in learning more about flexible signposts and bollards for your parking lot? Contact FlexPost today!